Blog

In and Outs of International Intermodal Boxes

Understanding International Intermodal Containers

International intermodal containers are essential for global logistics, seamlessly transferring between ocean, rail, and trucking networks. These containers adhere to international standards, ensuring efficiency in transporting goods worldwide. However, their movement requires understanding the size specifications, transportation procedures, and regulatory compliance.

Container Sizes and Specifications

International intermodal containers come in standardized sizes, with the most common being 20-foot and 40-foot boxes. These containers are made of corrosion-resistant steel or aluminum and built to withstand ocean freight conditions. Unlike domestic intermodal containers, which are typically 53 feet long, international containers are optimized for global transport and fit within ship holds and international rail networks.

Intermodal Rail and Port Access

Once international containers arrive at U.S. ports, they transition onto rail or truck for inland transport. Railyard procedures require pre-arrival clearance, security screening, and verification of driver credentials. Truckers must ensure chassis availability, as containers need to be mounted on a chassis for over-the-road movement. One key requirement for port and rail yard access is the Transportation Worker Identification Credential (TWIC), issued by the TSA. This credential is mandatory for truckers entering secure intermodal facilities, ensuring compliance with federal security regulations.

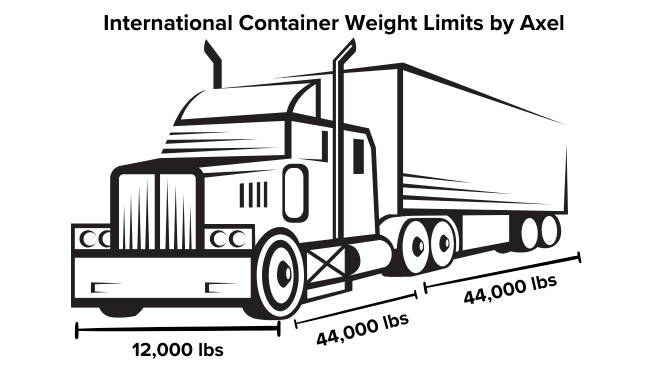

Weight Limits and Load Restrictions

Weight restrictions for international containers vary depending on the mode of transport. The Federal Highway Administration mandates a maximum gross vehicle weight of 80,000 pounds for trucks, which includes the tractor, chassis, and container. International shipping limits typically cap container weights at 67,200 pounds, including tare weight. Proper weight distribution is crucial to prevent violations, and truckers must ensure cargo is evenly loaded to comply with regional axle weight regulations.

Navigating International Intermodal Transport

Moving international containers efficiently requires an understanding of the logistics involved. While there are occasional hurdles like port congestion, chassis availability, and customs requirements, planning helps carriers avoid unnecessary delays. Ports can experience backlogs, so staying informed on container availability and scheduling pickups early is essential. Since chassis shortages may occur, checking with depots in advance ensures that the necessary equipment is available when needed.

Customs clearance is another important step in the process. Ensuring all required paperwork—such as the Bill of Lading, Import Security Filing (ISF), and Customs Entry Summary—is completed accurately can prevent unnecessary hold-ups. Carriers who familiarize themselves with these processes will find international intermodal transport to be a smooth and predictable operation.

With the right approach, international intermodal transport can be a reliable and profitable opportunity for owner-operators.

Sign Up

Shipping Freight? Get our new E-book.

Download our free e-book "Is there a future for Intermodal Marketing Companies?" and get DrayNow updates delivered straight to your inbox.

"*" indicates required fields